Technical Parameters

(1) Inspection range of wire rope: Φ16-80mm;

(2) LMA inspection uncertainty: <±1%;

(3) Flaw positioning accuracy:≥99%;

(4) Inspection speed: 0-6m/s;

(5) Monitoring speed: 0-20m/s;

(6) Passing-through capability: Non-interferencewith warp, grease or deformation;

(7) Clearance between sensor and wire rope: 10-30mm;

(8) Max. amplitude of wire rope: <10mm;

(9) Sensor sensitivity: 1.5V/mT;

(10) Signal-to-noise ratio: S/N>85dB;

(11) Max. sampling rate: 2048times/m;

(12) Working voltage: AC220V±10%/50/60 Hz;

(13) Communication network: WIFI or industrial Ethernet;

(14) Docking communication protocol: TCP/IP, Modbus;

(15) Ingress protection: IP67;

(16) Working environment: -40℃-+60℃/RH 95%;

(17) Continuous working hours: ≥168h;

(18) Service life of equipment: ≥10 years;

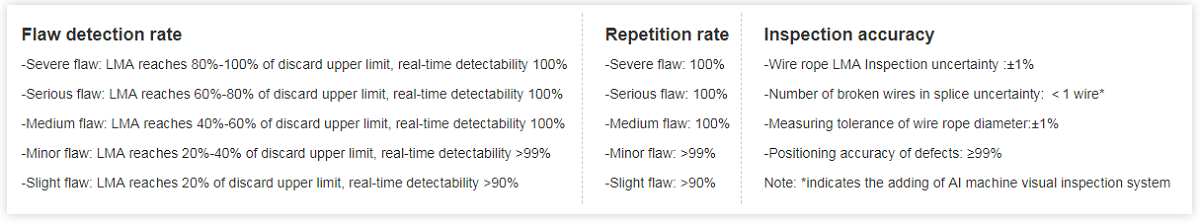

Flaw Detectability

● Severe flaw: LMA reaches 8%-10% , real-time detectability 100%

● Serious flaw: LMA reaches 6%-8% , real-time detectability 100%

● Medium flaw: LMA reaches 4%-6% , real-time detectability 100%

● Minor flaw: LMA reaches 2%-4% , real-time detectability >99%

● Slight flaw: LMA reaches =2% , real-time detectability >95%

LMA reaches >1% , real-time detectability >95%

Inspection Repeatability

● Severe flaw: 100%,flaws inspection waveforms basically coincide

● Serious flaw: 100%,flaws inspection waveforms basically coincide

● Medium flaw: 100%,flaws inspection waveforms basically coincide

● Minor flaw: >99%,flaws inspection waveforms basically coincide

● Slight flaw: >95%,flaws inspection waveforms basically coincide

Inspection Accuracy

●Steel wire rope, coiled tubing metal cross-sectional area (LMA) loss rate detection error: < ±1%

● Broken wires quantitative error i n one lay length: <1 wire*

●Steel wire rope, coiled tubing dia. measure error: ±1%*

●Steel wire rope, coiled tubing measuring error of wire rope length:<0.2%

●Flaw positioning accuracy:≥99%;

What can

I do-——It can inspect all kinds of wire rope flaws such as internal, external broken wire,

abrasion,

corrosion, deformation, fatigue etc.