who I

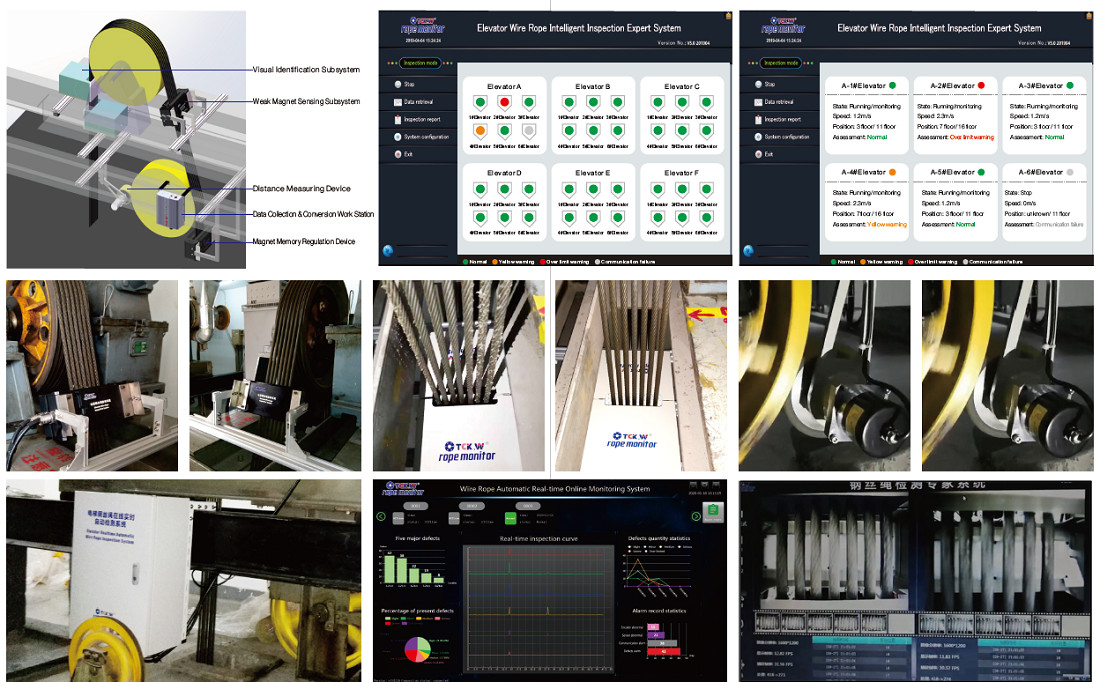

am——Elevator Wire Rope Intelligent Inspection Expert System

What can

I do-——It can inspect all kinds of wire rope flaws such as internal, external broken wire,

abrasion,

corrosion, deformation, fatigue etc.

Inspection Function

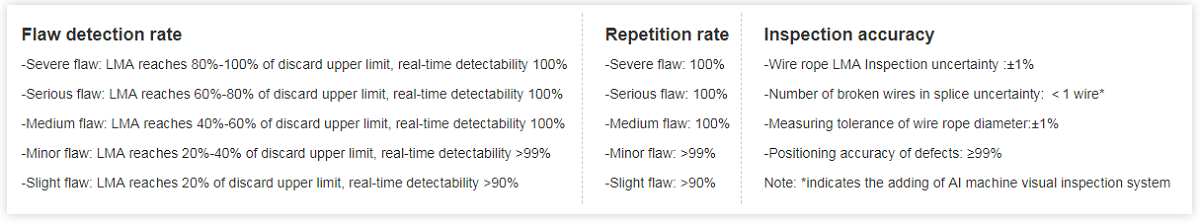

1. Efficient and accurate detection ability tobroken wire, abrasion, corrosion andfatigue of steel wire rope.

2. Fast and accurate identification ability tobroken wire quantity and other defects

3. Fast and accurate measuring ability to wirerope diameter change

4. Accurate positioning ability to wire rope defects

Basic Parameter

1. Space between Sensor and Wire Rope:10-20mm

2. Inspection Speed :0 - 6m/s;Monitoring Speed:0 - 30m/s

3. Rope Range:10-30 mm

4. Visual Identification Resolution:1600X1200PPI

5. Visual Identification Frame Rate: 40FPS

Working Condition Parameter

1.Temperature:-10℃-55℃;Humidity:≤95%RH

2. Ingress Protection:IP54

3. Alarm Function: Real-time warningof security status.

4. Operation Condition: Suitable for allkinds of elevator working condition.

![5da807d3465d3.jpg 3(K`T5G5~]4B2$~WSYQDWBP.jpg](/uploads/img1/20191017/5da807d3465d3.jpg)

![5da807ef66d5b.jpg 3(K`T5G5~]4B2$~WSYQDWBP.jpg](/uploads/img1/20191017/5da807ef66d5b.jpg)